At Affordable Granite we and our suppliers take great care to supply the best quality stone at an affordable price. As part of our commitment to quality we regularly visit our suppliers to inspect the shipments, review their facilities and working practices, and to find the latest stone trends

Affordable Granite and our Suppliers

THE PRODUCTION PROCESS FROM QUARRY TO KITCHEN IS COMPLEX AND FASCINATING

Granite is mined in large blocks, typically measuring 3m by 2m. These massive rough cut blocks often do not give any indication of the beautiful granite colours. Each block is carefully numbered and inspected for cracks and flaws. Samples are regularly taken from the blocks and laboratory tested for hardness, colour and other features.

Once a block of granite is ready for processing, it needs to be cut into slabs. First the block is trimmed to give a good square edge.

Nero Assoluto block

Granite block being trimmer using a wire cutter

Block being sliced by a cutter saw

“Cutter” saws use a large circular saw to slice the trimmed slab.

At Affordable Granite our experience leads us to select slabs that have been cut by a gang saw. This is similar to the bread slicing machine you see at your supermarket, but on a much larger scale. The advantage of gang sawn slabs is that each slab cut from a block will have a very consistent thickness.

A Gang Saw

Granite Gang Saw Grinding Grit

Parallel diamond coated cutting bars are drawn through the slab using sophisticated cutting grits.

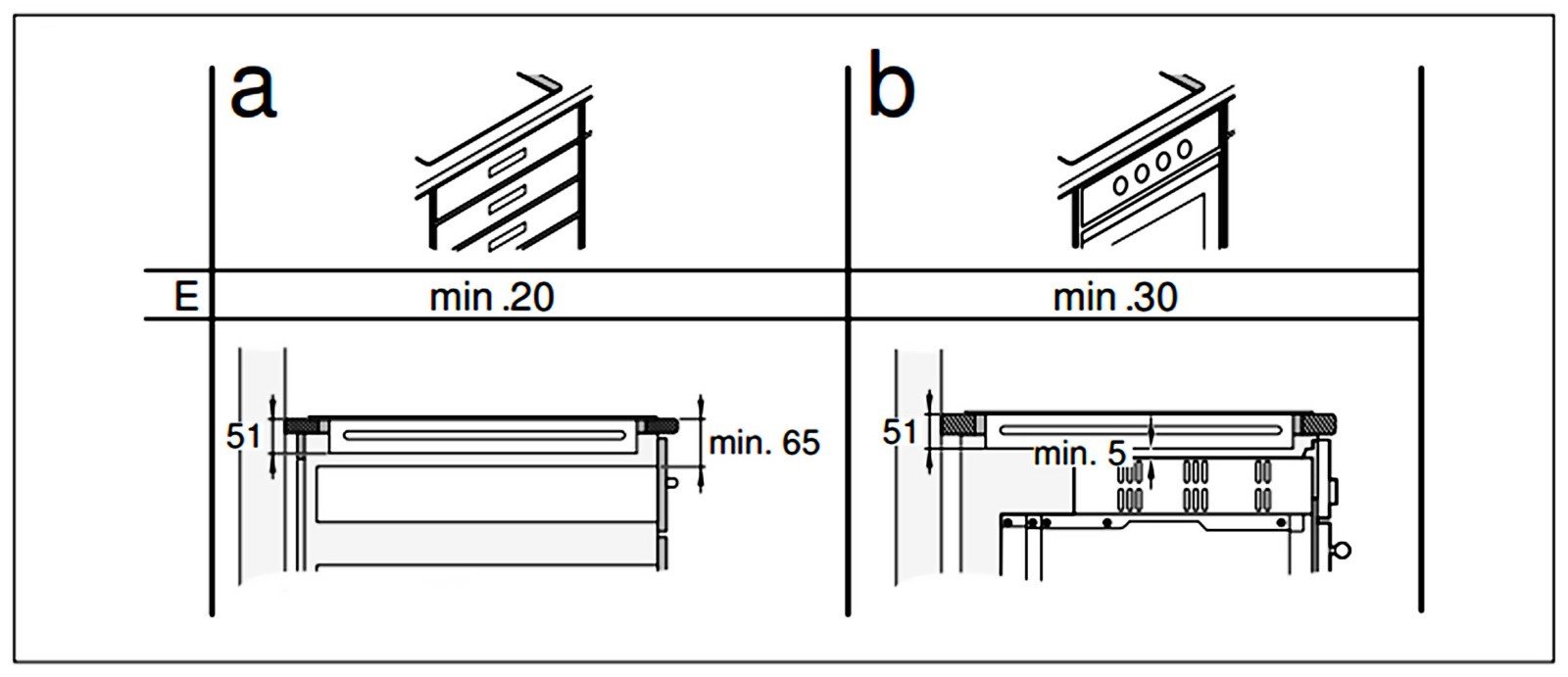

By placing the bars at exactly the correct distance apart, any slab width can be obtained. We purchase our slabs 30mm thick for worktops and 20mm for upstands and splash-backs

A block cut into slabs on the gang saw

Resin being applied to a Nero Assoluto slab

The sawn slabs are then coated in a resin to protect the stone surface. The resin is then cured in a hot oven. At this stage the rich colour of the stone becomes visible. For some very fragile granites a plastic mesh is attached to the rear of each slab.

The resined slabs are then surface polished using diamond and ceramic discs. Whilst it is possible to polish a slab by hand with the assistance of a Jenny polisher, the most consistent quality is obtained using a line polishing machine. These computer-controlled, laser guided machines draw the slabs slowly past oscillating polishing disks which polish the resined surface to the beautiful finish you desire in your kitchen.

Inspecting a line polishing machine

The latest Italian line polishers are installed at our suppliers

The slabs polish is then carefully checked

By inspecting the stone at the suppliers prior to shipment we can ensure the high quality of granite we specify is consistently being delivered. The inspected slabs are then carefully packed using wooden crates into containers which we then ship to the UK using scheduled sea services.