Vein-matching in marbled quartz worktops

Around 18 months ago I wrote two blog pieces about batch-matching in granite and in quartz. In the second article I touched on the subject of vein-matching, and posted a picture of work from another company that was so bad I daren’t share it again.

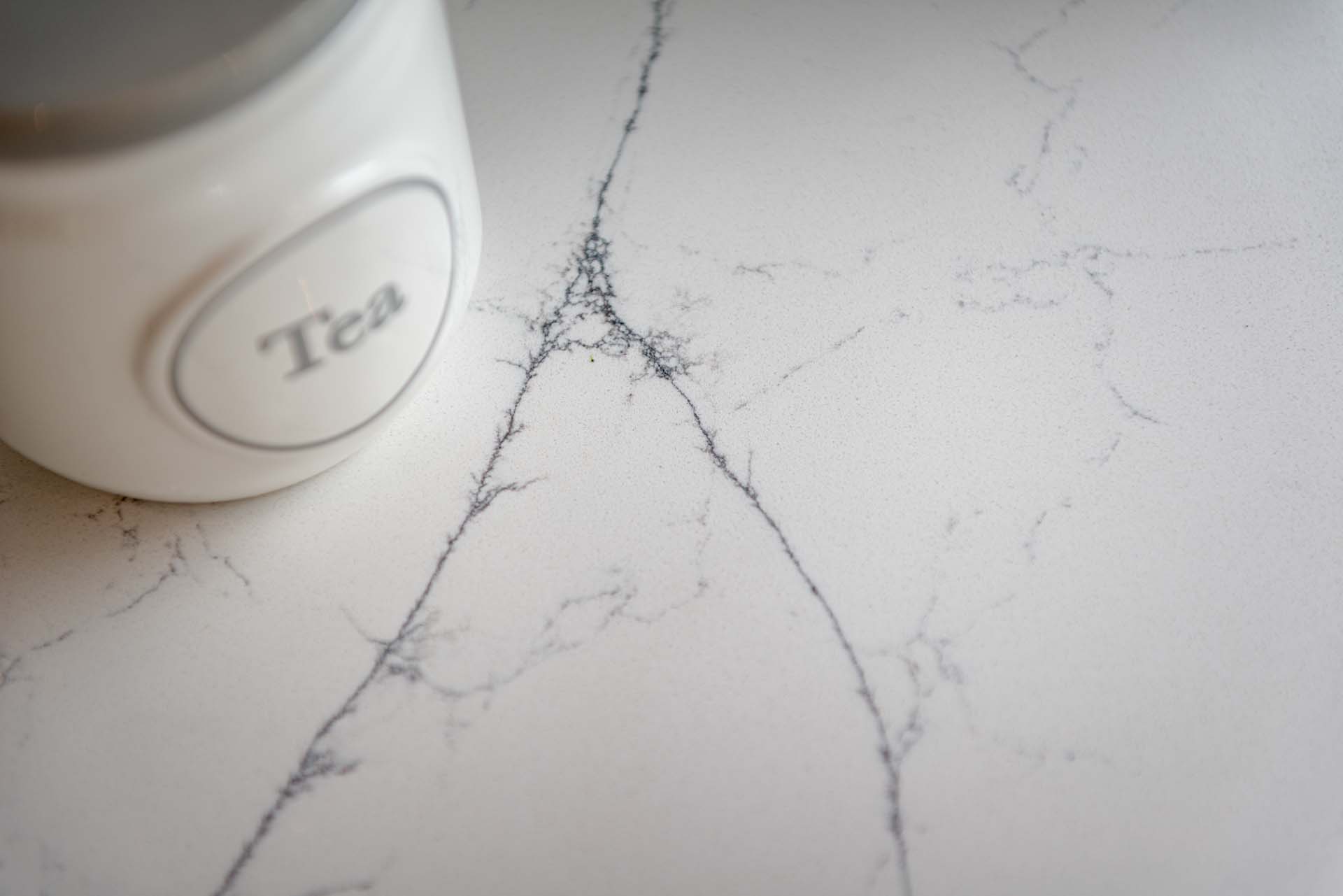

But I do need to write again about vein-matching. The steady growth in big-vein marble-look quartz has led to our templaters, sawyers and fitters being more conscious of this issue than ever before, and it is right for our customers to have some awareness of the challenges too.

Vein-matching in quartz worktops: the three basic situations

The “simplest” situation is simply where two quartz worktops need to butt up against each other. Although on the face of it quite simple, this may be the most problematic because large areas of stone may be involved – and very often (as in this case) at right angles to each other. This is where the availability of symmetrical (bookmatched) slabs can be a real help, as as to give us a variety of angles of vein to play with.

The second common situation is where stone is needed in both horizontal and vertical planes – such as an upstand or splashback. In this kind of case we are careful not to cut the upstands from separate sheets; wherever possible, upstands are made from the same slab as their worktop, so as to get more or less continuous veining. I say more or less, because the 20mm of upstand that has to drop behind the worktop always creates a slight jump, but it isn’t bad.

Note that where the worktops are 30mm thick, the upstand as initially cut has the back sawn off so as to get down to a standard 20mm thickness.

The third situation is where a windowsill above an upstand takes the stone back to the horizontal again. In this case we are dealing with an external corner – the edge of the quartz is going to be visible. This immediately presents a challenge as not all man-made materials are “full-bodied” – the veins don’t necessarily run right through them.

Most marble-look Dekton and other “sintered particle” materials are simply printed on – and this becomes glaringly obvious in this kind of situation, although it is painful to my eye at ordinary edges and cutouts as well.

But many “quartz” materials are also not completely full-bodied. Classic Quartz Alaska Bianca is partially successful, with some veining running right through, but exposed edges are, to be honest, the weakest link in the kitchen. however, as the vein carries on along the windowsill, the effect deceives the eye – overall it is really good.

Vein-matching in quartz worktops: complex projects

And here you can see all three of those elements… The veining runs from the sink run, onto the hob run, onto the upstand, and out onto the windowsill. This requires very considerable skill in our templating and workshop processes, as well as some flexibility in the use of material to make sure you can get the match.

Put bluntly, that flexibility makes vein-matching more expensive than not bothering. And, to be honest, the willingness to push for doing the job properly, and having the skills to make it right, is one thing that sets a serious quartz worktop fabricator apart from the also rans. We are proud of our track record for getting the vein-matching in marble-look quartz worktops consistently right.

It’s just another reason for choosing Affordable Granite.

We are Affordable Granite, the leading granite installer in Surrey, Sussex and across the South East. We believe that if a job is worth doing, it is worth doing well. We have seen too many bodges from other firms to be satisfied to go down the easy path. If you are looking at worktops in any veined stone – be it granite or quartz – go to a firm that will take the pattern matching seriously. For questions, queries and quotes connected with any aspect of worktop installation or kitchen design, please don’t hesitate to contact us on 01293 863992 or by email on sales@affordablegranite.co.uk/ .

Images ©️ Andrew King Photography