Variation in Stone for Quartz Worktops

Just a week or so back we look at variations in batch/block in granite slabs for worktops. This week we are looking at quartz. Many people do not think there is any reason for variation in a man-made product, although we only have to think about paints or dress material to remind ourselves that the man-made stuff varies too! Why does stone for quartz worktops vary? What are the reasons for poor matching of quartz between (or even within) batches?

(For a general introduction to how engineered stone for quartz worktops is made, take a look at this Silestone video.)

A Variations between batches

1 Raw material variations

We are used to thinking of quartz as a “man-made” product, but we need to remember that up to 93% of what is called quartz may be ground rock straight from the quarry. Just as granites vary as the quarrymen move through the rock, so quartzite for engineered stone can shift in colour tone. With so much of it going into the product, it is not surprising that variations can be seen in the final mix.

2 Errors in the man-made content

Dyes in that 7% give the colour to the batch. It isn’t hard to imagine that they are fairly powerful – and minute errors in the quantity of colourants can cause marked variations in slab colour.

3 Cleaning errors

No quartz factory/production line in the world only makes one product. A move from batch to batch. Ideally there will be a complete clean down of the machinery between batches. We suspect that when there is pressure on, this doesn’t always happen perfectly. If even a little of the mix from one product is transferred into the first batch of the next product, variation will result.

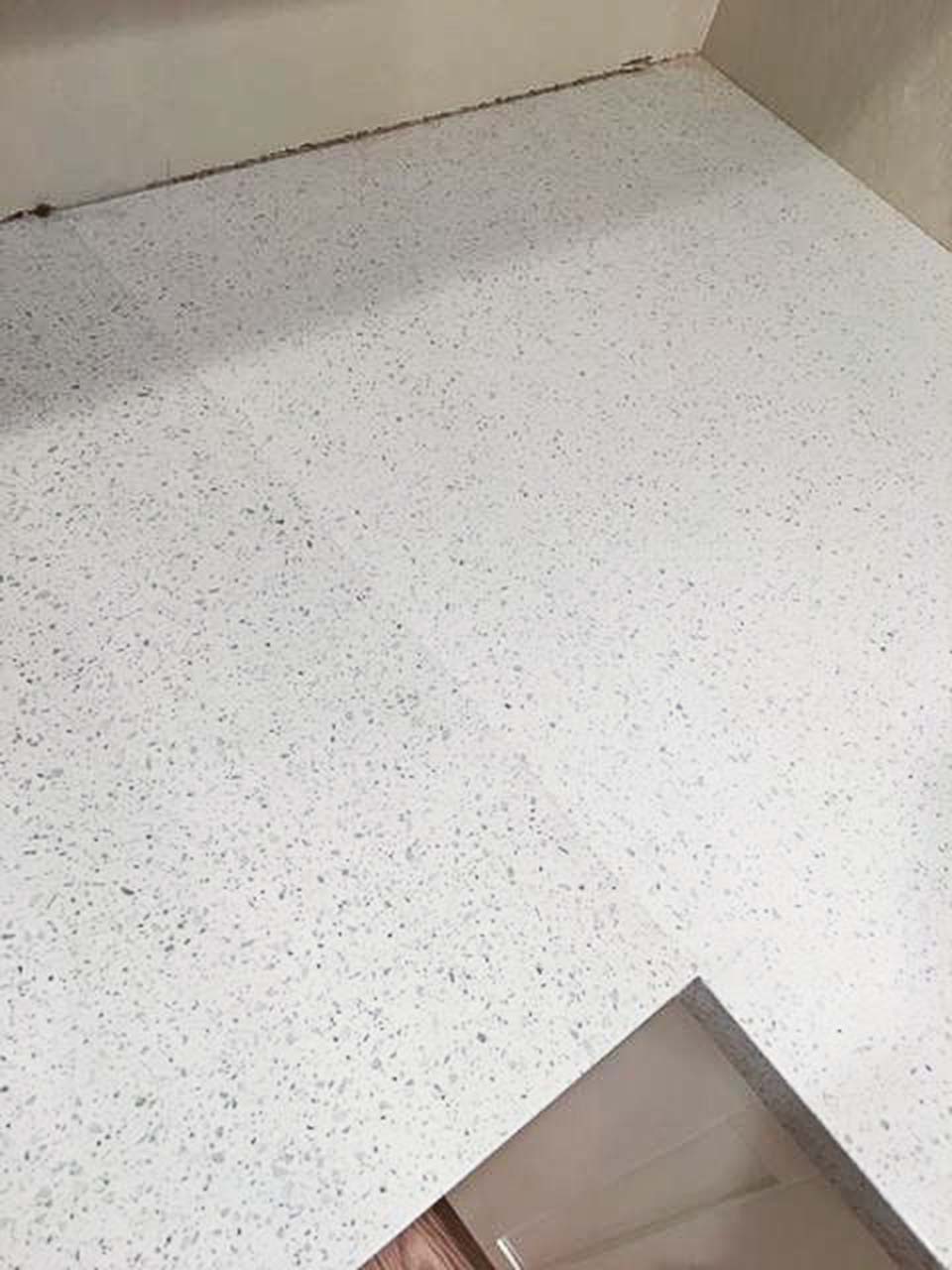

A pretty horrible example of an installation done with badly batch-matched quartz. NOT one of ours!

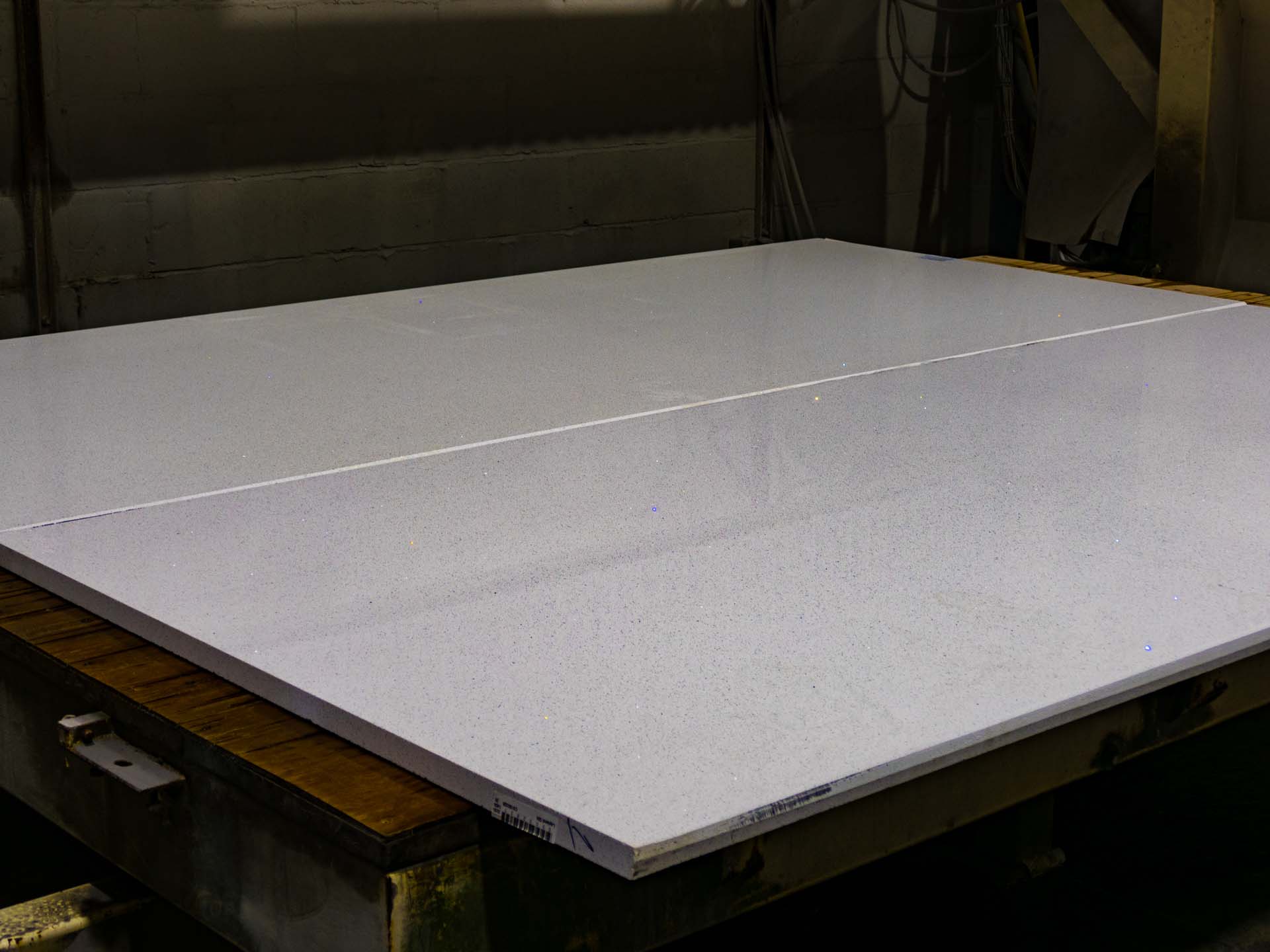

To many eyes, and to my camera, there is not a lot of difference between these three slabs of sparkly white quartz. They are supposed to be from the same batch – sourced from a relatively well-known European manufacturer…

… but the lads in the warehouse spotted problems. Taking the same photo, but pushing the contrast and saturation up in Photoshop reveals a different story. The slabs vary greatly between them, and there are also unacceptable variations even across individual slabs. Rejected by AG!

B Variations within batches and even slabs

4 Mixing errors

We suspect that some batches are not mixed as well as they might be. This can be evidenced by colour variations across the slab, in products where no such variation is intended/to be expected. See the images here, which come from what we think of as a “middling” brand of quartz worktops.

5 Poor supply chain control

The big-name suppliers maintain rigorous control over all slabs – every slab we receive is numbered individually, together with its batch number and date of manufacture. Some manufacturers don’t do this, and we suspect that slabs from different batches get bundled together at times, with no paperwork to control or evidence that process. The big brands score here.

C Long term variations

6 Alterations to the recipe/mix/design

The slow change in colour tone of the raw material (see 1)) that happens as a quarry is used can lead to steady and lasting alterations to the appearance of a given product. However, there may be something else going on when a quartz changes appearance, sometimes even quite sharply.

We have at least twice, and from one of the biggest names in engineered stone / quartz worktops, seen sharp changes in appearance between initial samples and slabs and the ongoing production which comes through a few weeks or months later. We are aware that some products have been launched and then subsequently altered. This may well be that a change to the mix is seen as advantageous in the market, but you can imagine that such changes can leave us seriously embarrassed when customers have chosen the original version.

Our advice on this one would be to allow certain manufacturers to “bed in” their new products a bit before purchase, and if at all possible, to look at the actual slabs you will be getting when they come in. Of course, if we see that there is variation or change to the design, we will always contact customers to alert them, however inconvenient this may be for our factory process.

Ouch! This is a real double whammy. Matching up the veins of big-scale marble slabs is not easy… but I have NEVER known our sawyers and fitters make quite such a gratingly painful hash of the big-veined marble look in quartz worktops as this. But – more subtle but possibly more significant – the two slabs are also really not compatible in themselves. The veins are far softer and warmer in the right hand run and the overall background tone is different too. This may be a batch problem – it may even be a company running out of a product and substituting something else altogether.

I just showed this to Ben, our Workshop Manager. I think I’ve made him ill for Easter!

Summing Up

All of this should not put you off quartz worktops! Far from it – the technology that goes into engineered stone keeps moving forward and quartz is popular for good reason. But you do need a company who take quality control seriously – from the moment the supplier’s lorry brings slabs to our warehouse to the moment the fitters leave your home. Here at Affordable Granite, we are proud to be able to offer one of the most consistent and genuinely caring installation services around, where quality for our customers comes first.