A new CNC saw for our granite worktop factory

One of Andy Phillips’ first big equipment investments in our granite worktop factory when he arrived as owner and MD was an Achilli bridge saw. He bought a second, more heavily computerised saw in 2016. Now, in 2020, and in the aftermath of the Covid crisis, we are moving up another gear. We have replaced the first of the Achilli machines with a GMM Extra 400 CN2 CNC saw.

The Coronavirus epidemic has been a serious challenge for our industry as for all others. If it has had one silver lining for us, it is that it has pushed up the emphasis on home cooking and baking. The kitchen is more important than ever. And, if the crisis has pushed some firms to the wall, it is the strong that survive. Andy has been keen to keep pushing ahead with automation and ever greater efficiency in the workshop.

The GMM Extra 400 CN2 CNC Bridge Saw

Our old Achilli saw on the way out…

…and our new GMM saw on the way in

What does CNC mean and what are the benefits?

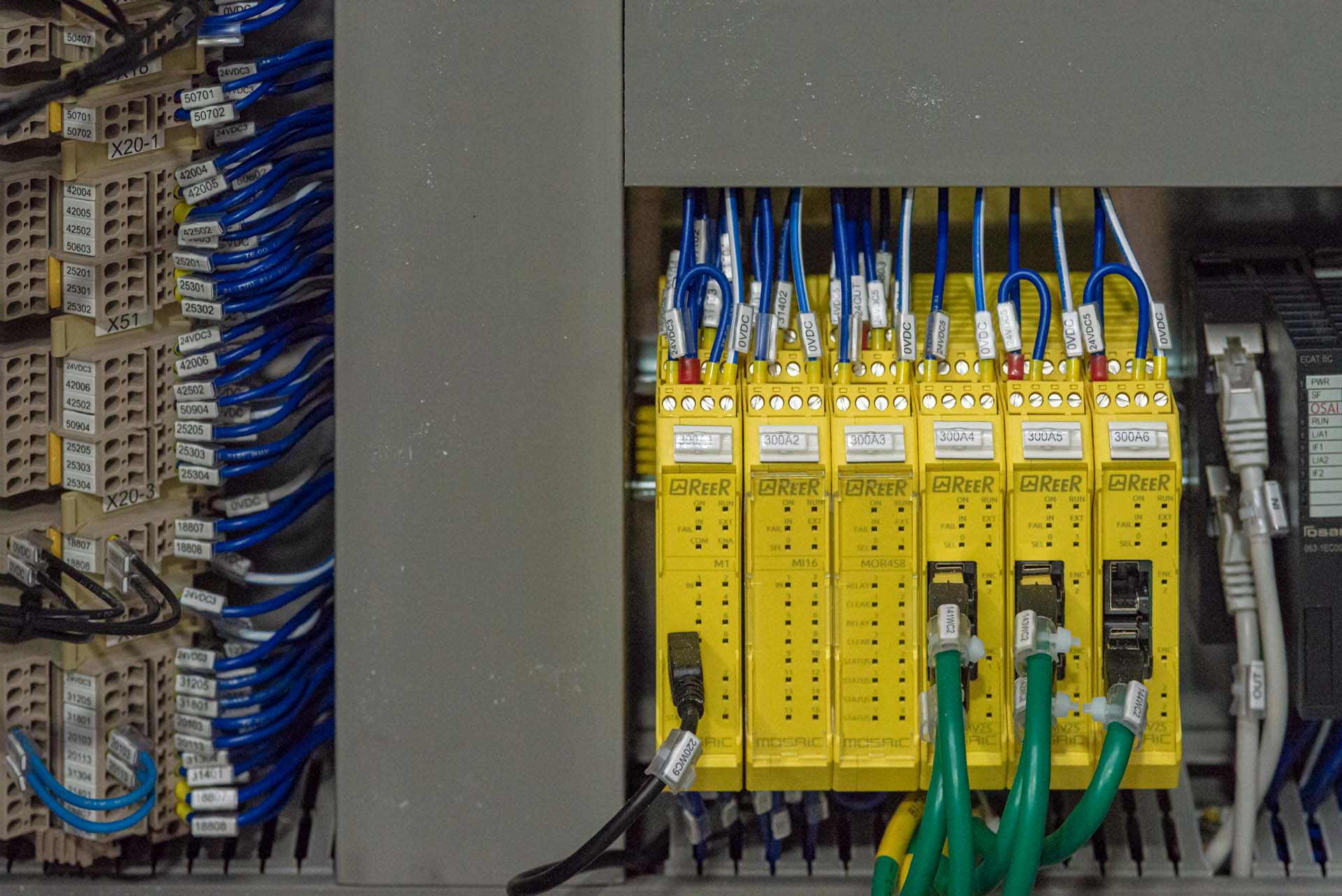

During set-up it is pretty obvious that the heart of the machine is digital/electronic

CNC stands for Computer Numerical Control. CNC machines of many kinds, from granite saws to 3-D printers, are controlled by computers, using digital parameters, as opposed to by hand or using some kind of physical cam or pattern. General accuracy of cutting, repeating identical routines and (in this case) making angled cuts in the vertical plane for mitred joints, are more easily achieved than ever before.

In the light of recent concerns about airborne silica dust, the reduction in hand-tooled work for mitring, as well as getting the sawing process behind a protective wall, has to be a good thing for the health and safety of our staff, as well as for our productivity and quality.

Main operator’s interface and master CPU

Secondary computer, switching, connection box, with its own Air Conditioning unit

CNC saw - setting up and training in the granite worktop factory

As I write, the saw is in place and is being set up. Machines of this scale and complexity aren’t quite “plug and play”. We do not expect to see meaningful output for a week from the arrival date. But work is in progress. I will add a few more pics here and on Facebook as things develop.

Installer’s tools laid out and ready to go

Setting up the GMM Extra 400 CN2

Affordable Granite bought the new CNC saw through GMM’s UK agent, Roccia Machinery of Derby. Roccia are sponsors of the Worktop Fabricators Federation, of which we are founder members. Our industry is not huge, and the stone, machinery and tooling suppliers are well-known to us worktop fabricators. We are glad of a warm relationship with Roccia!

We are Affordable Granite, the leading granite installer in Surrey, Sussex and across the South East. We are committed to ongoing investment in and improvement of our granite worktop factory, achieving great quality for the customer at a decent price, and protecting our own staff health and safety and the environment in which we work. For advice and help on your stone worktop installation, don’t hesitate to contact us on 01293 863992 or by email on sales@affordablegranite.co.uk/ .