Cutouts in granite and quartz worktops: the basics

One-and-a-half bowl sink cutout in Dekton Trillium

Cutouts often cause confusion for granite and quartz worktop customers. There is something about the series of questions – how many cutouts? polished or unpolished? – that makes eyes glaze over and brains freeze up.

Cutouts also cost money. Given that they are holes, how come you have to pay for them? And why are some more costly than others?

I hope that this brief article will demystify the world of cutouts, just a bit.

For general information on different types of sinks and the words used to describe them, please see our article here.

The most basic cutout: the small circular hole

Intermac Master CNC cutting a taphole

Tap holes are the most basic kind of cutout in a granite or quartz worktop. Straightforward mixer taps, bridge taps, hot water taps like the ®Quooker, filter taps – all need tap holes, most commonly 32mm. Similar holes are needed for air-switches, as used to control waste disposal units.

Tap holes are quick and easy, even with hand tooling, and extremely straightforward on a big CNC machine. This is reflected in the price.

Larger circular holes can take slightly more setting up and time, but are still pretty straightforward. Pop-up sockets and waste holes for sit-on vessel style sinks require this kind of hole.

For an article on the uses of pop-up sockets and their relevance to island installations, please see here.

Pop-up electrical socket in a Kashmir Gold granite worktop

The unpolished cutout: hobs and top-mounted sinks

A contemporary topmounted sink, requiring an unpolished cutout

The sink is an 1810 Company Zenduo 156-f

With topmounted sinks and hobs, a flange sits on top of the worktop stone. You cannot see the hole through the stone, so it doesn’t have to be polished. An unpolished cutout takes much longer than a taphole, but is still much quicker than a polished cutout, so is still relatively inexpensive.

People sometimes talk about “flush mounted” hobs and even sinks. For an article on these, please see here.

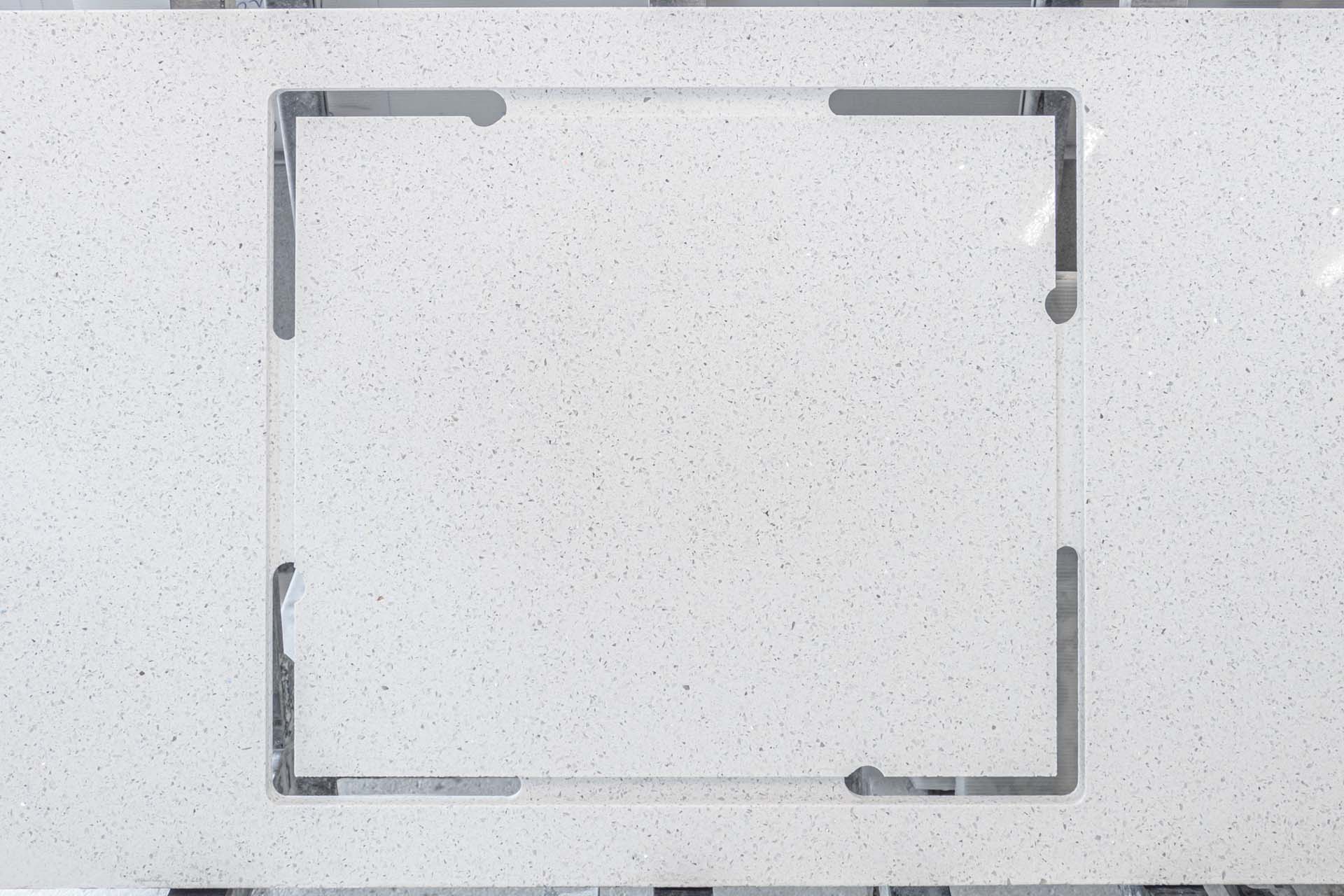

Unpolished cutouts are often quite large. Hobs, especially, can be quite deep, front to back, and that makes the bars of stone in front and behind fairly thin. To avoid breakage to the cutout during transport, we often don’t cut the centre out completely in our workshop. Instead, we leave ‘lugs’ of stone to be cut through on site, using an angle-grinder or similar, often in the drive or garden of the property.

A hob run in quartz, ready to leave the factory, showing the semi-cut hole

The hob cutout ‘lugs’ are finally cut through on site – almost always outdoors keeping the dust out of your home…

…then it is just clean it up, peel off the protective plastic sheet, lift the worktop away from the “hole” and carry it in!

Polished cutouts: undermount sinks

Simple Zenuno 15 sink in copper set under a Caesarstone Excava worktop

The undermount sink cutout is a staple of any solid stone worktop factory. Kitchens with ranges do without hobs, but everyone needs a sink, and there is no better way to show off your solid stone than the classic undermount. Because the sink is under the worktop, and the hole through the stone is visible, the hold must be polished. Polished cutouts are the most expensive holes, as they require the most labour if done by hand, and the largest number of “passes” of different heads on the CNC machine.

Cutting out a sink hole in Black Pearl Granite. At this point an initial ‘starter’ hole has already been drilled (at the left) while the tap hole is visible at the right. After the cutout is made, the machine changes heads several times, bringing the side walls of the cutout up to a fine polish.

The cutout that isn't a cutout: drainer grooves

Drainer grooves in a Black Galaxy worktop

Drainer grooves aren’t cutouts but they also take significant time to do – whether by hand or on the CNC – and so cost money. Once again, they are a staple of any worktop factory – they look right, and demarcate the sink area. For more information on drainer grooves – their pros and cons – please look at our article.

First stages of drainer groove cutting in a Black Granite worktop. Notice that these are done before the sink cutout that goes with them. That way the grooves cut perfectly and neatly into the sink and the bevels look right.

We are Affordable Granite, the leading granite installer in Surrey, Sussex and across the South East. We have an outstanding factory allowing us to produce hob and sink cutouts to any spec efficiently and with a great finish. For questions, queries and quotes connected with any aspect of worktop installation, please don’t hesitate to contact us on 01293 863992 or by email on sales@affordablegranite.co.uk/ .