Templating granite kitchen worktops: What is a template?

When I first started working at Affordable Granite there were many things that I needed to learn. The most mysterious and new to my ears was the whole idea of templating. It took me a long time to get my head around the mysteries of templating and of the workflow from template to installation. Since then my experience has been that templating is also a great mystery to our customers. We all know what it’s like when tradespeople almost sneer at our lack of knowledge; we don’t want to be like that. So here is the clearest explanation we can do about templating: what is a template and why is it important?

Your dream kitchen with granite worktops – how to make the dream a reality?

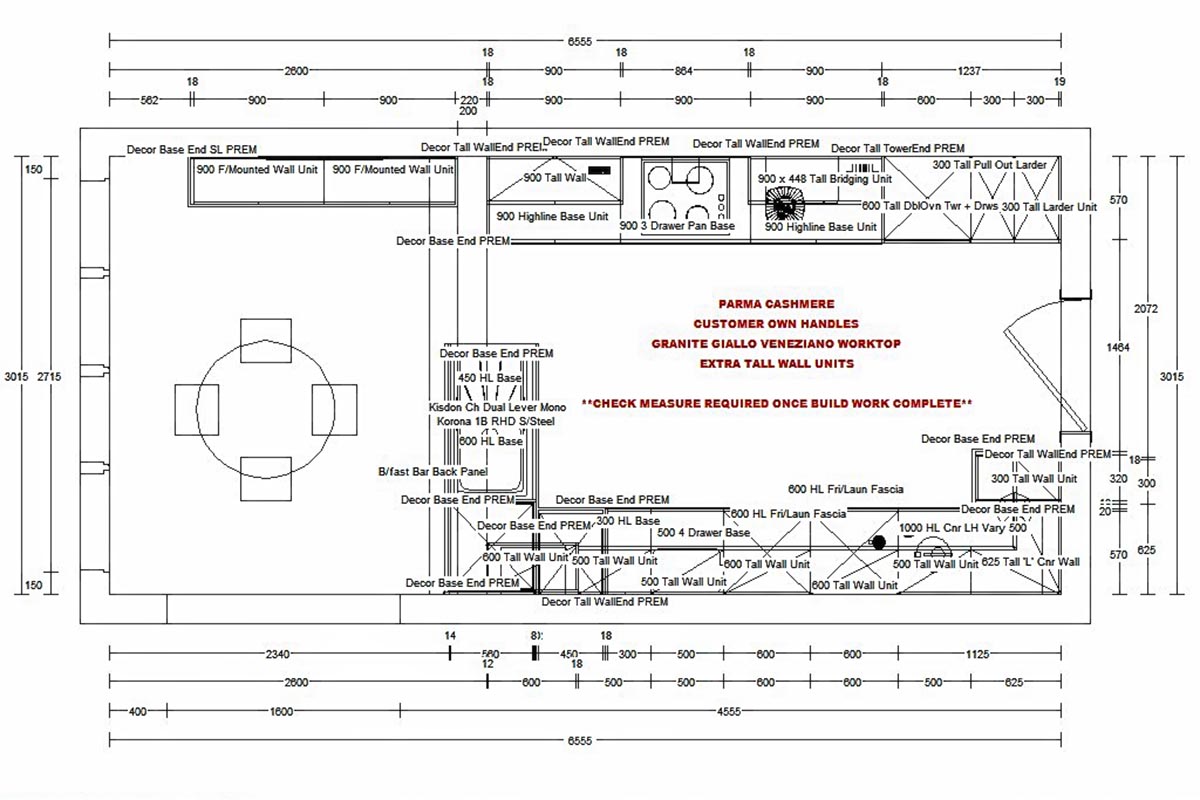

Planned kitchens and actually constructed kitchens are not the same thing. The measurements and diagrams on which we base our quotations are NEVER absolutely true to what is actually built – and certainly not at the kind of accuracy which is needed for the worktop fit to be acceptable. Kitchens aren’t square, kitchen units aren’t perfect…. nothing is precise.

But our fitting needs to be. For a kitchen wall to be only 5mm out of true along its length would be unusually good, and you would never notice the “error” without measuring it. Kitchen units are often placed square to each other, so in a wonky kitchen there may be a bit of a gap opening behind them at one end of the run. Again, no big problem. But if a kitchen worktop with a 10mm overhang follows that wall and has a 5mm variation in the overhang along its length, it will look seriously horrible. And if the gap at the back varies by 5mm, and there is no upstand, there may be a problem when filling or tiling.

This is why we never manufacture from customers’ initial measurements. Taking measurements – in fact making physical or virtual mock-ups of the worktops – is what we call templating. It is the hinge between our quote and sale process on the one hand, and the manufacture and fitting of your worktops on the other. It is at the very heart of our process, and will define the look of your kitchen. The templater carries tremendous responsibility; errors here are frighteningly expensive, while a really good template makes the fitters’ job far easier.

Templating granite kitchen worktops: Traditional, physical, templates

Down through the years, most granite worktop companies have used corrugated plastic sheeting, such as Correx®, to make physical templates. Such templates have the advantage that they can be offered up to the job area when made to double check them, and can also be annotated. On the other hand, they can easily be damaged or even lost.

The biggest benefit of the physical template is seen with big-patterned stones. Where matching of veins is critical, it is far easier to visualise what is going on when we can put physical templates on the slabs. Many customers want to be able to guide us with their vision of how the stone should be used – “We would like to lose that dark bit”, “Can we have the sparkly crystal patch in the middle of the island?” etc. You can see that here, as Ben, our Workshop Manager works with a customer to help them realise their dream granite worktops in Belvedere Leather.

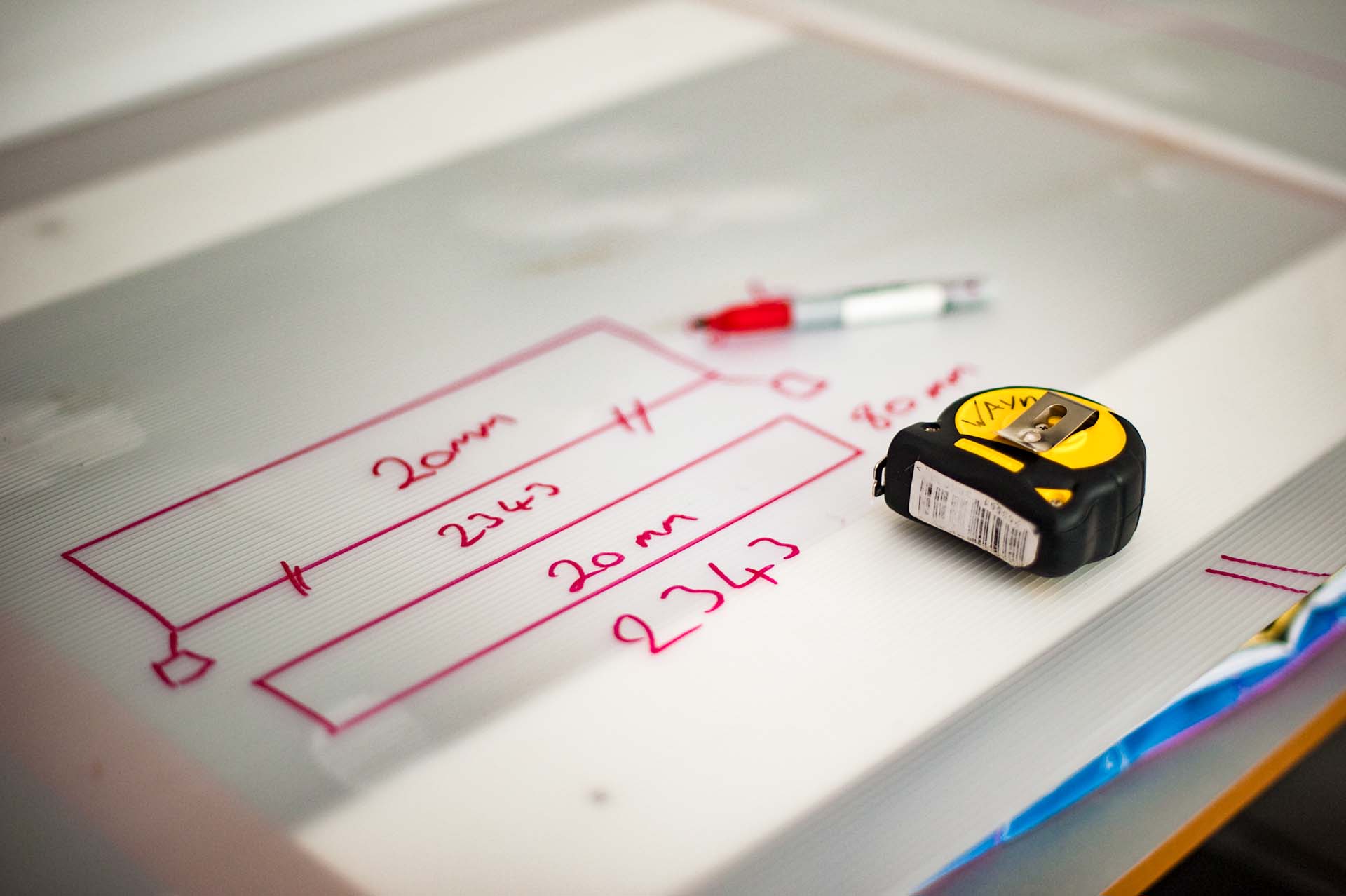

Traditional templating using physical material involves the most basic and familiar of the craftsman’s tools: straight edges with levels, pens and pencils, knives and, of course, measuring tapes. Here Michael templates a deceptively simple kitchen. Just a single run and an island – but with all of the worktop to be mitred and made to look 50mm thick, with mitred downstands on the island and a thick wooden breakfast bar to butt up to, all using a big-vein marble-look quartz which needed vein matching, this was actually a very technical job.

Templating granite kitchen worktops: Digital templates using the laser

Laser templating has been around for a number of years, but it is only fairly recently that we have moved over to the system for most installations. This has been partly because it is only quite recently that we bought a computer controlled saw which can take numerical input direct from the template.

Laser templating has a number of advantages:

- Accuracy – laser templating allows very consistent results due to its overall accuracy

- Speed – the data from the laser set up is fed back to the AG office before our templator has even left the customer’s site.

- Durability – digital template data can be stored and backed up across multiple devices and platforms, with no mess or storage costs, and far less risk of loss.

- Environment – using numbers instead of plastic sheeting is clearly an advantage!

On the flip side:

- Laser templates are not easy to immediately visualise on site – you can’t offer one up to the work. As a result, there is a need for a certain amount of double and triple checking, with extra measurements back-checking the initial ones. And our templators still get their tape out for a basic measure up of the room!

- Laser templates are not easy to immediately visualise back in the workshop – it is much harder to “see” how the veins or pattern should flow through the job. As a result, we still tend to template big-pattern jobs using Correx.

In these images from installations in three homes, Michael can be seen taking initial tape measurements, calibrating the laser against fixed points on the wall, and using green tape as reflection points for the laser measurements. Data from the laser is fed straight into a tablet mounted with it on the tripod. The whole thing can then be sent back to the AG office for processing into the kind of data which will drive the saw for slab cutting.

Some of the images come from the same house as the physical template above. In that particular case, the job was so technically demanding and so critical on all measurements and with the vein matching that we decided to go over the top and use BORTH methods. On top of which, it gave me, as photographer, the chance to shoot both approaches in one hit!

Templating granite kitchen worktops: How can the customer help?

Ultimately, a granite worktop firm has to look after its customers even better than it looks after its product. Not just because that is what customer service is all about, but because we need your help to make your worktops as accurately and effectively as we can. We often tell people, “You don’t need to be around for fitting, but you must be on site for the template!”

That is because templating must incorporate decisions about how you want things done. Which side will the drainer grooves go? How do you want your corners done? Do you want the hob centred on the base unit or in the gap between the wall units? Our templator won’t want you to be breathing down his neck the whole time – it is intensive work that needs serious concentration – but there will be plenty of questions where your input is critical.

The biggest way you can help us in this process is by only calling us in to template when you are really ready. We emphasise this in our paperwork, we have a checklist which we ask all customers to sign off, and we even have an article about being ready. Please read this, and make sure that you only ask us to come over to measure when you really are ready.

We are Affordable Granite, the leading installer of granite and quartz bespoke kitchen worktops in Surrey, Sussex and across the South East. For samples, quotes and any questions connected with any aspect of worktop installation or kitchen design, please don’t hesitate to contact us on 01293 863992 or by email on sales@affordablegranite.co.uk/ .

Images of templating and installations © Andrew King Photography