With the expansion of our factory area, 2015 has been a significant year for us in increased capacity and in efficiency and ease of production. All of that new space needed machinery to suit, and over the year we have massively upgraded both our CNC and our edge polisher.

The CNC is used principally for cutouts for sinks and hobs, but can actually make all kinds of curved and shaped edges and other features. With the trend to larger and more complicated kitchen islands, good production capacity for curves is more important than ever. This new machine can polished straight away to a high shine.

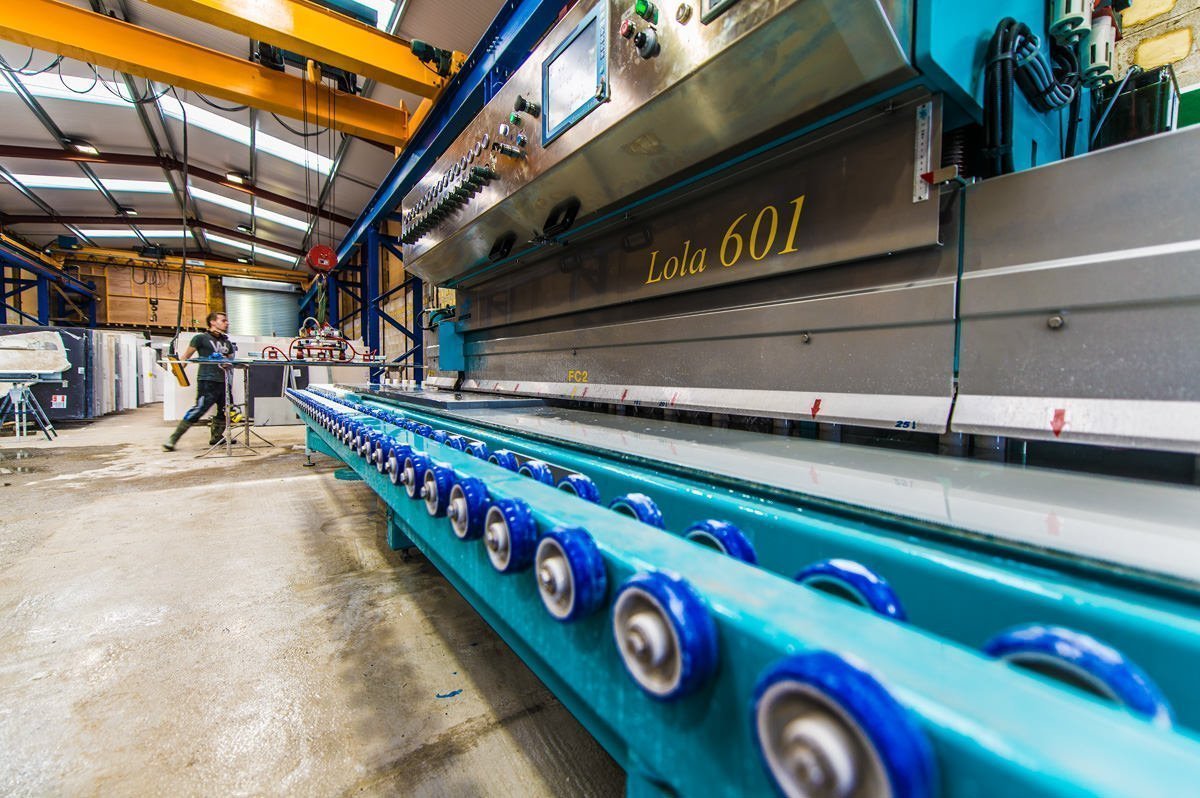

And it is the edge polisher which deals with straight lines… this is the fastest and best quality edge polishing machine we have ever owned, completely replacing the previous unit. Our craftsmen with their hand-polishers now have a new standard of excellence to live up to when they finish off the curves, internal corners and other features that the edge polisher can’t handle.

Both of these machines have been invaluable in the context of the growth in our Dekton business in particular. The extreme hardness of this worktop material slows down the machining process, which would lead to significant delays and on-costs if it weren’t for having the right kit.

The larger workshop space and production capacity has been essential: we are now able to install up to or even over 20 sets of granite or quartz kitchen worktops each week. Production and installation capacity has had to be matched by the strengthened team in the office. 2015 showed yet further growth over 2014 and there have been plenty of orders to generate and process. Our supply-only business has also grown, with vanity tops, hearths, shelves, pizza oven slabs, speaker stands barbecue bases and other small pieces all being made from offcuts from time to time.

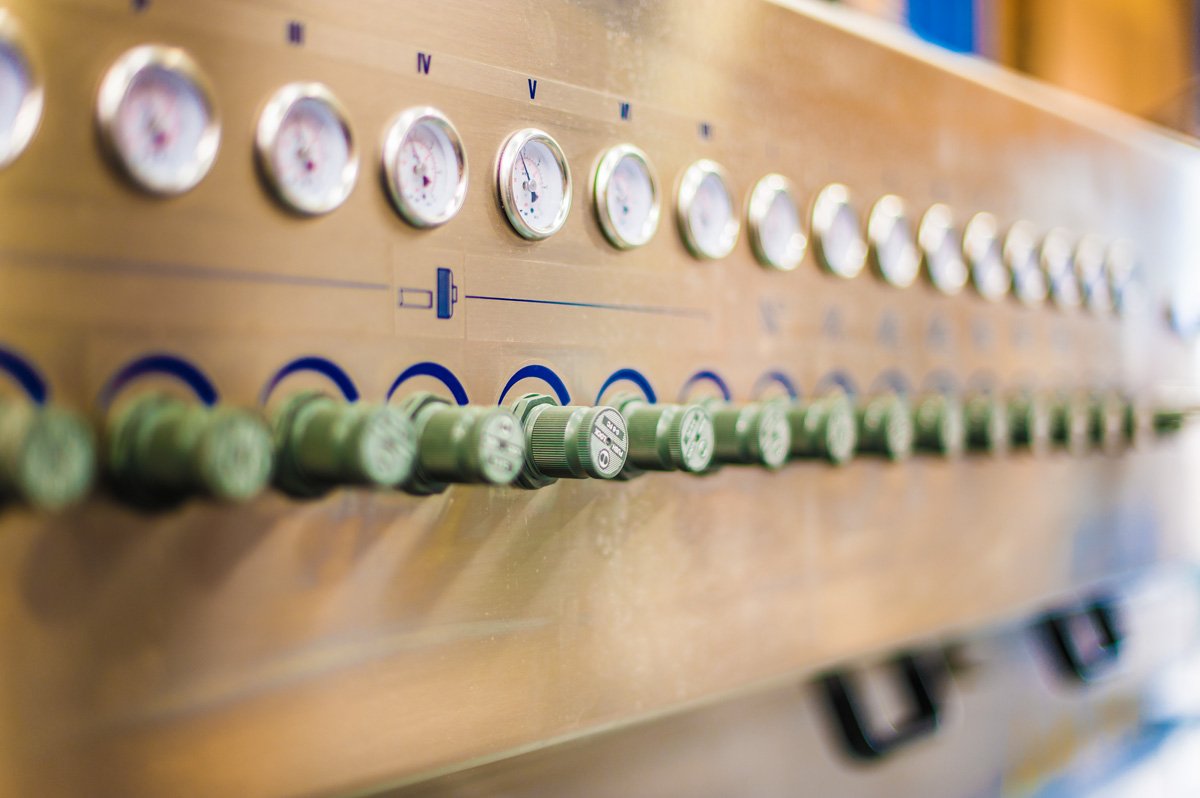

Pressure gauges and controls on the edge polisher

The Lola 601 in use.

The new CNC – arrival

Off the lorry

In situ and in use

Hob cutout ready for final cuts in Dekton Aura. We often leave the stone in place with these small “tags” holding it as this strengths the slab during transport and installation.

The massive water flow around the machining head.