What is the difference between granite and quartz? Which is better?

The question about granite and quartz is just one of many questions about different worktops options. For a general round up of worktops materials, please see our “Magic Bullet” article.

What is the difference between granite and quartz? Which is better, granite or quartz? These are probably the most frequent questions that people ask us. The answer to the first is (fairly) simple… and to the second, more complicated. At the simplest level the difference is between natural and man-made stone.

Granite is natural; quartz is man-made.

What is called “granite” in our industry is not necessarily what a geologist would call granite. In practice, “granite worktops” are made from a wide variety of stones, all of them hard, and all of them natural – granite worktops are made from rock that has come out of the ground.

“Quartz” on the other hand is man-made. It is properly called “engineered stone”. To make it, small pieces of natural stone, glass, mirror and other hard products are mixed with a petro-chemical resin and compressed in machines in a factory. For some products dyes are injected so as to give the appearance of natural veining, but the product itself, however much like a natural stone it looks, is manmade.

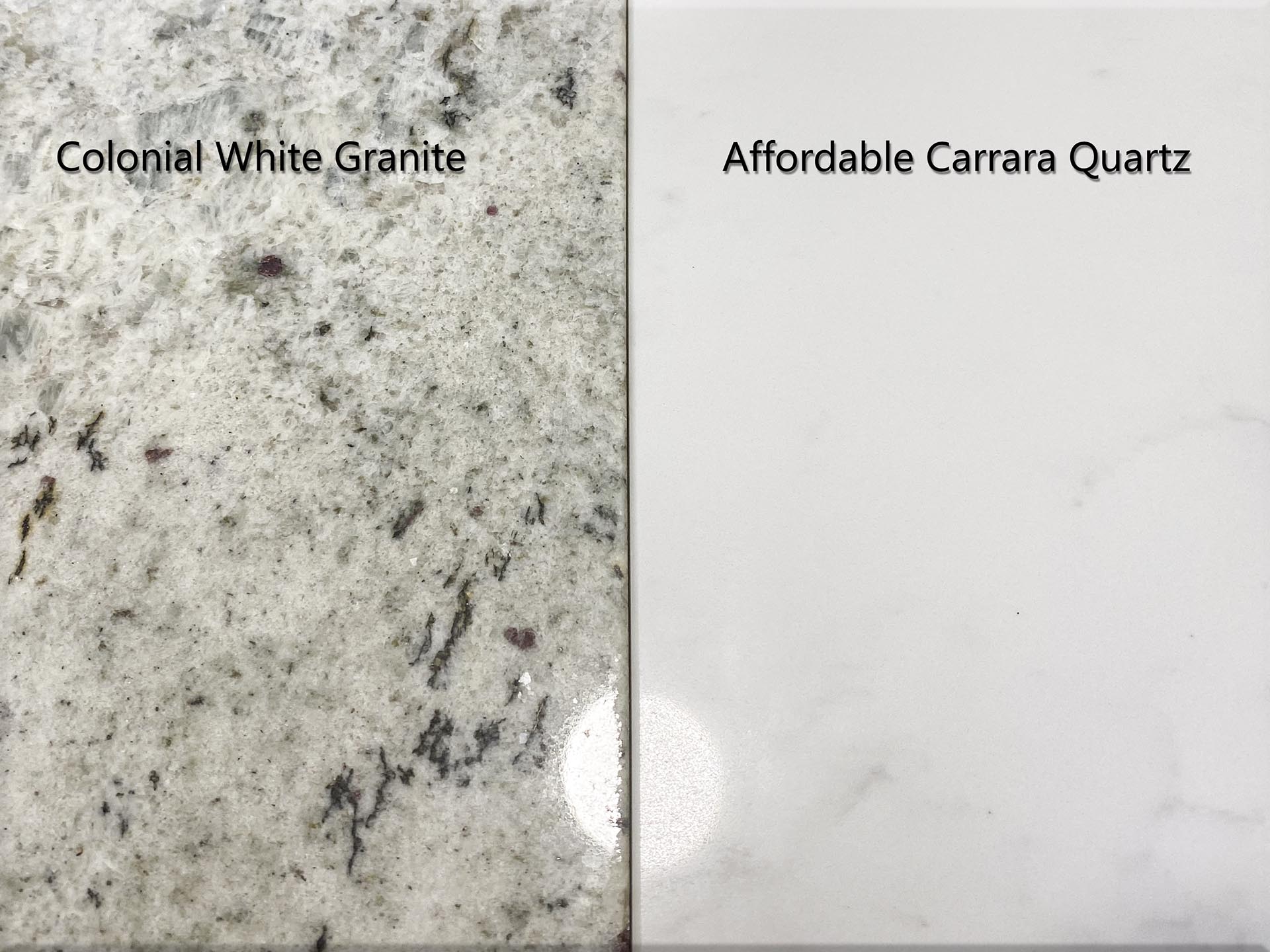

The second question, “Which is better?” is more complicated. Our general rule of thumb is to recommend granite in dark colours and quartz in light colours. Here are the reasons:

Caesarstone White Attica Quartz Island

Lemon Spice Granite Worktops

1 Staining

Coffee marks on a quartz worktop

Many substances common in kitchens can mark or stain worktops. Obvious examples are tea, coffee and wine, which are water-based, and tomato, spices (especially paprika and turmeric) which can be at their worst when carried by oil.

Staining can be looked at under two headings: surface staining and subsurface staining.

Surface staining can occur with all materials. Residues of food (or other pigmented substances – toddlers with paints? dirty grease on fingers from engine or bike repair work?) get onto the surface and mark it.

Subsurface staining can only occur where there are pores in the material and where the worktop is translucent or even partially transparent. Of all the worktop materials, this can occur most with some light-coloured granites, where a crystalline structure allows seepage under the surface AND can show the result as a subsurface stain.

It is worth noting that quartz manufacturers tend to claim that “granite stains but quartz doesn’t”. What they are referring to is subsurface staining – and on that one point they are correct. But subsurface staining is only part of the picture, and their oft-repeated claim can be seriously misleading. Please read on.

Surface Staining

In general, highly polished surfaces are easier to clean and get stain free than matt surfaces. Unless you opt for a honed, leathered, caress or other finish, your granite worktops will be shiny. As such, they will behave in a way not so different from glass, ceramic or stainless steel when it comes to getting them clean. Polished granite is really good!

Quartz is also available in non-polished finishes, often under names like velluto or suede. But the point here is that, even in what is called a polished finish, quartz is significantly less shiny than granite. As such, it is harder to remove stubborn stains. And in the very popular white marbles and other light-coloured quartz worktops, those stains can show.

This is not disastrous news, and, overall, we still recommend light-coloured quartz. But we do want to be open about the issue, especially when some quartz manufacturers skate over it, to say the least. And we would say, on the basis of our own tests and experience, that “big brand” quartz tends to perform better at this point. As with so many things, you gets what you pays for, and the best, most cleanable, surfaces generally come from the big names.

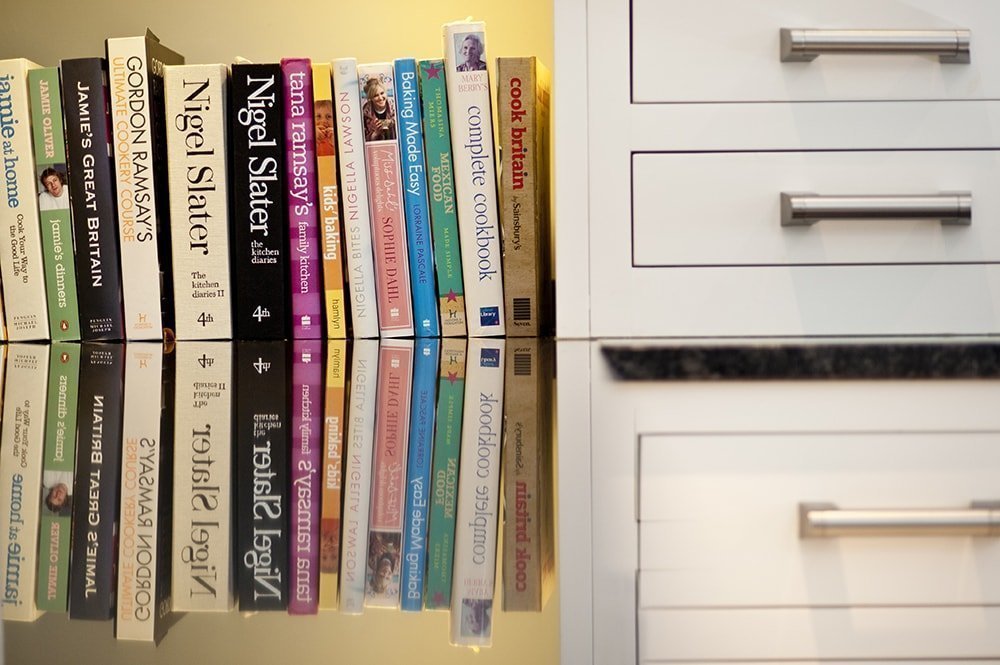

Reflection on the surface of a Steel Grey Granite worktop

Samples of a granite and quartz worktop showing the difference in reflecting a ceiling downlighter.

Both samples would be said to have a “polished finish” but the higher shine of the natural stone is easy to see.

Subsurface Staining

This is where quartz really scores. Because of its resin base, quartz is completely non-porous. That doesn’t mean, as we have seen, that it is completely proof against all staining, but that no stains can get below the surface. A pen mark or curry stain may need some treating, but it will only be on the top of the stone.

There is no problem for many granites either. Dark “granites” tend to be genuinely igneous rocks – crystallised out of molten magma way beneath the earth’s surface. As a result they are low in porosity and have great resistance to any penetration by stains. In addition, being dark or black, they are not translucent or transparent: even if a stain WERE to penetrate, there is very little chance that it would show.

Lighter “granites” are generally metamorphic rocks formed from the coming together of sands and gravels, with other minerals percolating through in solution, and the whole layer being heated and compressed over time. They tend to have more and larger pores than the igneous rocks, AND the light colours and translucent crystals mean that any stains that penetrate can be visible. Getting a sub-surface stain out is all but impossible, although they generally fade over time, and are far less obvious where there is some colour in the stone. We always urge customers who buy light coloured granites – which many still do, due to the beauty of the natural patterning – to watch out for any break-down in the surface sealing, especially near the sink. Where the stone becomes darker when wet, you know that water is entering the surface, and where that kind of water-bridge is present in the stone, a colour in solution can very easily get beneath the surface.

A patch of water on an unsealed piece of Colonial White granite.

The darker patch left after the water has been wiped off, showing water penetration into the stone. When this starts to happen near your sink you need to reseal the granite. Never fear – this is not a difficult process, and we have a full page explanation (with video!) of how to go about it.

2 Scratching

Although both granite and quartz are very hard, it is nevertheless possible to scratch them – with other pieces of stone, ceramic or glass, or diamonds etc. One difference we have observed in samples of granite and quartz in our office is that dark granites tend to scratch to a dark colour, whereas quartz looks lighter where it is damaged. The result of this is that black quartz can look far tatty more quickly than similar-toned granites. This is a significant advantage of black granite. It would probably be fair to say that the high-end brands of quartz seem to suffer less from this issue, and, as ever, patterned stones disguise issues better than plain ones. It would also be fair to say that the big samples in our office suffer a very high level of wear and tear, being bashed against and slid over each other – worktops in a normal kitchen will not experience anything like the abrasion we see here.

Fine scratches on a piece of Nero Assoluto in our showroom, where other stone samples have been dragged across it. The coin is a 5p piece.

Scratches on the edge of a piece of black sparkly quartz, where other samples have hit or scraped over it. Note the lighter colour in the scratch.

Both these images show EXTREME abrasion – they are not kitchen-typical.

Staining and scratching are the two biggest issues which need to be considered for most kitchen worktops in most locations. For all the reasons given above, it is probably clear why we tend to favour quartz in light colours and granite in dark. But some caution is needed, especially in more economical white quartz, where surface staining may be a factor in a busy kitchen.

There are a few other differences, though, where one or the other product can have the edge.

3 Tensile/flexural strength

Because of the plastic element in the composition of engineered stones, quartz has a greater tensile strength than most granite as used for worktops. “Granites” themselves vary greatly in this respect, being very different kinds of stone; the truly volcanic stones are very strong, but some of the larger grained metamorphic rocks are comparatively weak. This can mean increased standard minimum clearances for cutouts, reduced maximum overhangs and, sometimes, overall run lengths.

With its higher strength, however, quartz worktops can be manufactured with easier tolerances, and at only 20mm thickness if required. For some styles of kitchen a thinner worktop is preferred, and in that case quartz is definitely the way to go.

Overhang on island in 20mm thick Cimstone Sines quartz

4 Ultraviolet Sensitivity

A garden tabletop in granite

The resin/plastic content in most quartz can be attacked and broken down by ultraviolet light. Therefore, for garden tables, barbecues and any other outside application, only natural stone or a ceramic worktops like Dekton® could be recommended until very recently. There are now, however,some specially-made ranges of quartz which can handle the UV and are suitable for outdoor installations.

For an article on garden kitchens with a general roundup of materials suitable for outdoor use, take a look at our blog.

Summing up

Remember, both granite and quartz are high end worktop materials. In some ways it is a bit like comparing a Porsche and a Ferrari – to anyone driving an old Ford the differences may seem academic! And it is important to remember that both products have great advantages in many situations, and there is no point overplaying the differences. When compared, say, to wood and all its maintenance issues, both stones are so much better! We hope that this “granite and quartz” article will be useful – please call us on 01293 863992 or use Live Chat if you need more help.

For an article looking at stone worktops versus laminate worktops, see here, and for a general round up of every possible worktop material with their pros and cons, please see here. You may also be interested in our article on heat resistance in granite and quartz worktops.

We are Affordable Granite, the leading granite installer in Surrey, Sussex and across the South East. Our philosophy has always been that giving full and honest information in an unpressured way ultimately gives us happier customers than a dishonest or hard sell approach. We hope that this article and others we publish has been informative. If you have any more questions, queries and quotes connected with any aspect of worktop installation or kitchen design, please don’t hesitate to contact us on 01293 863992 or by email on sales@affordablegranite.co.uk/ .